Fin Seal Pouch

Fin seal pouch are common use for most Inflatable products, Cost-efficient choice for low value FMCG products packaging, automatic roll stock.

Fin Seal Pouch

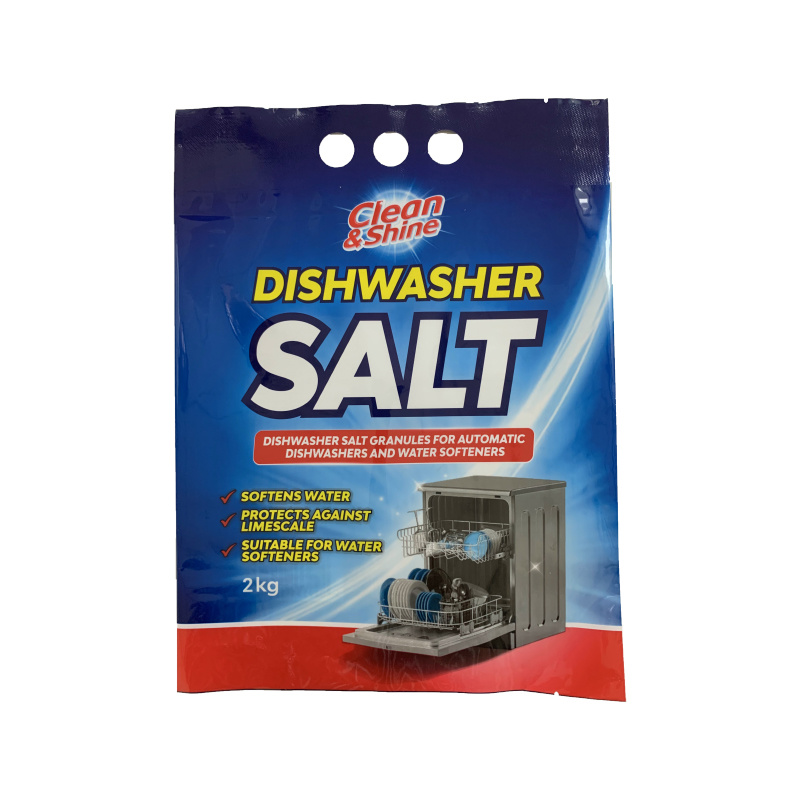

Simple Pillow Inflatable Pouch | Customized Print

Fin Seal Pouch is the simplest pouch with a back and bottom seal.

It can be made with fin seal on one side or lap seal, also called it Center Seal pouch or T-seal pouch, Pillow Pouch, Lay-flat Pouches. The Fin seal pouch is normally used for packing potato chips and fried snack foods

It is also used in packaging hard candies, gummy, instant noodles, and frozen dumplings. Common in the supermarket shelves is the packing Lay’s or chips as well as colorful gummy and candy grain.

Some fin seal pouch packing chips are filled with nitrogen gas inside making the fin seal pouches to look large and full, but in actual sense, the pouch is only filled with small quantities of products inside.

WE CAN DO IT

★ MOQ start from 20K as a start

★ With simple CMYK color process for attractive images

★ Most made with simple 2 layer clear or foil material structure, some with 3 layer material

★ Can be made with the sewing edge effect or euro hold adding.

Advantage of Fin Seal Pouch

● First of all, fin seal pouches are cheap, making them great for a startup business.

● They are also cheap and easy to ship.

● Unsurprisingly, they are quick to make, and you can order a very large amount at once.

● Fin seal, or pillow, pouches are lightweight, easy to open, and catchy to the eyes, and voluminous, bringing success to your business.

If you want to customize your own fin seal pouch, email us!

Make your own Pouches

* Leave your contact information to get a free product quote

Fin Seal Pouch FAQ

Q

What industries can fin seal pouches be used in?

+

A

Generally, the food industry is a huge market.

For fin seal pouches specifically, this food market can be expanded into the dry, inflatable, confectionary, and miscellaneous foods.

Dry foods include nuts, cookies, various snacks.

Inflatable foods mainly mean chips.

Confectionary foods encompass gummies, chocolate, gum, and various hard candy.

Other types of food include noodles, teas, powder sauces, and spices.

Sometimes, fin seal pouches are also used to package toys and a lot of other products.

Another surprising application is packaging magazines, collector cards, and promotional material!

For more details, you can also check out specific pouch applications, such as coffee pouches.

The material used for fin seals depends on the type of food in question.

Q

What are some opening designs for fin seal pouches?

+

A

There are 3 main tear notch designs: vertical, horizontal, and a pouring nozzle.

A vertical tear notch is similar to the asymmetrical seam (scroll up).

Both of them are good if your products are such that people are likely to pour them out in a bowl instead of eating right from the bag.

This works with smaller snacks.

A horizontal tear notch is similar in use to the symmetrical seam.

It is great if your products are big and likely to be eaten in one sitting right from the bag, like chips.

A pouring nozzle will have a similar effect as a vertical tear notch.

However, it is good if your products are really small, like tiny candy, powders, or even loose leaf tea.

Basically, something that will be partitioned into small portions over time.

Q

Are there options to make a fin seal pouch reusable?

+

A

You can request a zip, as mentioned above.

Another option is a pouch that can be taped together.

This type has a strip with an adhesive on one side of the film, which will seal the bag when a user overlaps the pouch.

Such a solution could be great for a big pouch of candy or some other snack.

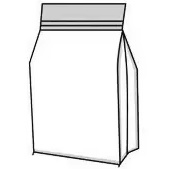

A tin tie is yet another option you can have with fin seal pouches.

Tin ties are good for bags that house coffee or loose-leaf tea.

Basically, the material at the top of the bag is rolled and has a metal strip in it.

The user can employ this strip to tie the top closed or roll it closed.

Q

What is the difference between a fin seal and a lap seal?

+

A

A fin seal is also known as a fold-over seam.

This is when two internal edges of the material are sealed together and folded over.

A lap seal, also known as the overlap seam, has an exterior edge sealed with the interior one.

Choosing the right type of seal depends on the material used.

A lap seal uses less material, so it is more economical.

However, it only works if both the outside and the inside materials are sealable.

This is possible if the material used is polyethylene (PE) or polypropylene (PP).

A fin seal is used when the sealing medium is on the inside of the material, making it more versatile and usable with more materials than the lap seal.

Q

What are the drawbacks of using fin seal pouches?

+

A

Compared to some other types of seals, the fin seal is not as strong and puncture-proof.

Also, despite being economical, fin seals do use more material than lap seals.

Fin seal pouches also have a relatively short shelf life of 9-12 months.

However, if you have a small family business, this may be a problem.

Finally, many business owners don’t prefer fin seal pouches anymore.

They order film rolls and package everything themselves.

While it is cheaper and faster, if you are a novice, fin seal pouches that are ready to go are easier for you to start off of.

Q

What are some additional design options and features for fin seal pouches?

+

A

You can request a zip to make your pouches reusable.

You can also add a valve for that same purpose.

Valves are usually used to dispense liquid or paste products, although, some powders will also work.

Another use for valves/vents is to strategically place them such that consumers can smell the aroma of the product to be convinced to buy it.

Another option is whether or not you want a clear window, so the consumer sees what the product actually looks like.

This is a great design option.

You can also request some type of a tear notch, an ergonomic handle, and a punch hole – euro or round.

ergonomic handle and a punch hole

Finally, you are free to choose the finish of the packaging – matte or glossy or a combination of both.

Matte finishes make your packaging look unique and interesting, as well as your label will be more visible.

Glossy finishes make your package look shiny and automatically grab the attention of your customers.

Q

What typical shelf life do fin seal pouches provide?

+

A

Fin seal pouches normally have 9-12 months of shelf life.

However, if you request a metalized PET material, you can prolong the shelf life to 15-18 months.

This range also depends on how good the seal is.

Q

How do you manufacture fin seal pouches?

+

A

Most fin seal pouches are made with 2 or 3 layers of clear or foil material.

The film is stretched on rolls.

Then it is formed into a tube; the sides are sealed together into a fin seal or a lap seal.

Finally, the bottom and top of the tube part are sealed to create a perfect pouch.

Common Accessories

Provide custom service

Lifting Handle

Self-sealing Zipper

Hanging Hole

Slider Zipper

What materials are used in fin seal pouches?

PETAL is PET with aluminum, which is metalized PET.

Kraft paper is brown paper material.

Film Structure

Common Uses

Polypropylene (PP-OPP)

Most widely used film. Often used in snack foods, candy, High barrier properties for air and light sensitive products

Foil Laminations

High barrier properties for air and light sensitive products

Polyester(PET)

Good heat resistance makes it ideal for products cooked in microwaves or ovens, such as garlic bread.

Low Density Polyethylene (LDPE)

Least expensive polymer film. Often used for shrink applications such as pizza, soap, cds, candles, etc.

High Density Polyethylene (HDPE)

High moisture barrier. Good for powders, cheese, electronic parts, etc.

Polyolefin

Premium shrink film for boxed candies, pizza, etc.

Paper/ polyethylene Laminations

Frozen food products such as pot pies and burritos

Glassine

High grease products

Valeron

Superior tear resistance for products such as chlorine tablets

PolyvinyIChloride (PVC)

High clarity and stiffness. Used in such items as greeting cards and candles.