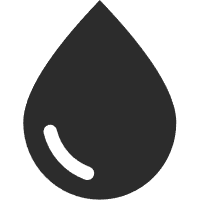

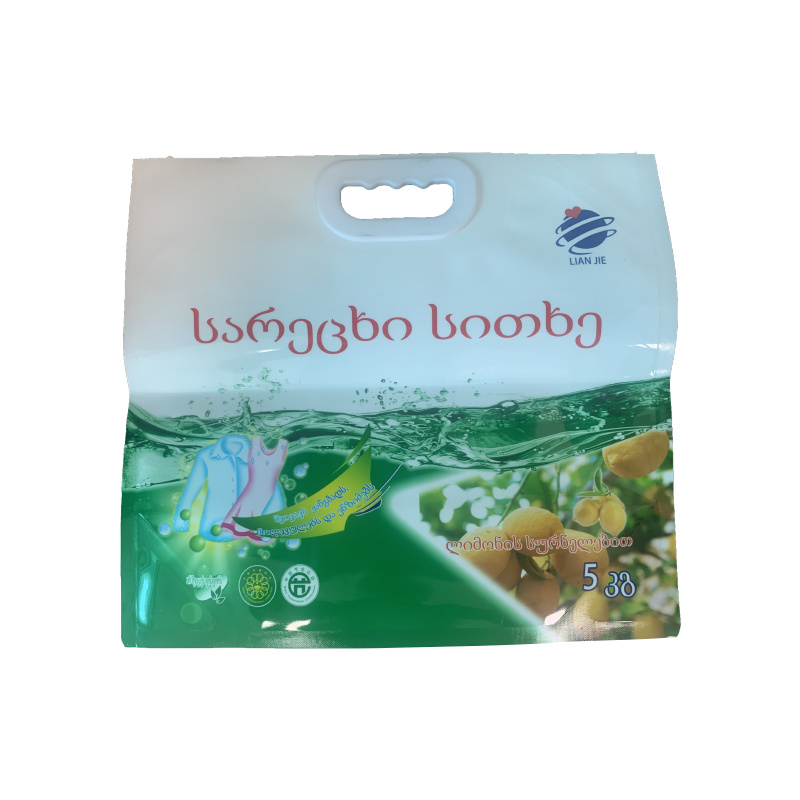

Washing & Care Pouches

Packaging bags are widely used in the packaging of shampoo, body wash, hair conditioner, facial cleanser, hand sanitizer and other kinds of washing and care products. Different brands and different positioning products will choose different materials and different designs of packaging bags to meet market demand and consumer preferences.

Washing & Care Pouches

Meet All Your Needs & Contact Us

When purchasing a series of packaging bags, it is recommended to choose the right material and design according to the characteristics of the product and market demand. At the same time, pay attention to the environmental protection and sustainability of the packaging bag, and choose recyclable or degradable materials to reduce the environmental burden. In addition, attention should also be paid to the tightness and durability of the packaging bag to ensure the safety of the product during transportation and storage.

Washing and care packaging bags play an important role in protecting products and promoting sales. With the continuous change of market demand and the improvement of environmental awareness, the material, design and function of our packaging bags are also constantly innovative and improved.

Make your own Pouches

* Leave your contact information to get a free product quote

Common Material

▲ Plastic material:

Polyethylene (PE) : has good softness and tear resistance, often used in low-temperature packaging, waterproof, seismic, dustproof, pressure proof.

Polypropylene (PP) : harder than PE, also has good tear resistance, is also a common washing bag material.

PVC: High transparency, often used in the need to show the appearance of the product, such as shampoo, body wash and so on.

▲ Aluminum foil composite material:

The packaging bag made of aluminum-tin-plastic composite film and other materials has hard texture, strong sealing, good moisture proof, anti-oxidation and anti-ultraviolet effect, and is often used for washing and care products that need to extend the storage time of products.

▲ Nylon film:

As an advanced moisture-proof material, it has super moisture-proof, breathability and fire resistance, and the barrier performance is also very good, which is often used in the packaging of high-end washing and care products.

Function and design

Protection function: The main function of the packaging bag is to protect the product and prevent damage by external factors during transportation, storage and use, such as extrusion, moisture and so on.

Display function: Transparent or translucent packaging bags can show the appearance and color of the product and attract the attention of consumers.

Information transfer: The packaging bag is usually printed with the product's brand, name, composition, use method and other information to facilitate consumers to understand and use the product.

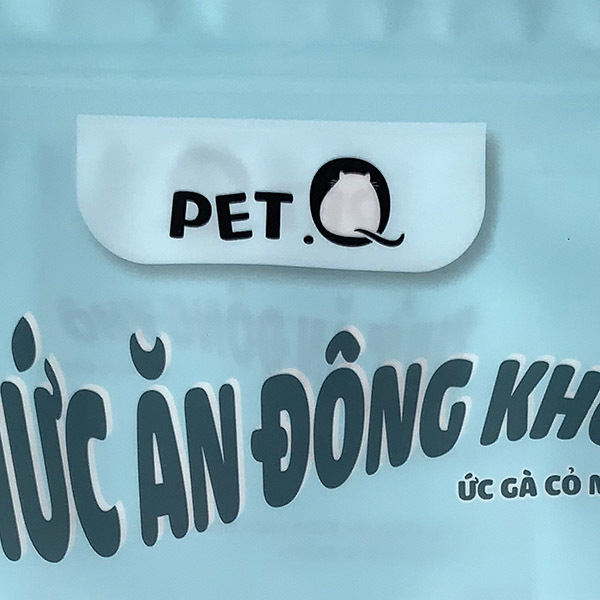

Portability: Some of the packaging bags are designed with a portable belt or hook, which is convenient for consumers to carry.

If you want to customize your own pouch, email us!

jack@jingranpack.com

Printing Technology

Provide custom service

Printing Matte Film

Printing Film

Window Design

Gold Stamping

Printing Laser Film

Exposed Aluminium

Local Bright Light

Brushed Scrub

General Materials and Characteristics

Material for Middle

Characteristic

OPP

Bright surface: With great transparency.

Matte surface: With shading effect and low gloss.

PET

(Polyethylene terephthalate)

Bright surface: Better heat resistance, oil resistance, drug resistance, barrier. Not easy to dissolve.

PA

(Nylon/Polyamide)

Heat resistance, wear resistance, puncture resistance, strong toughness and good softness. Good barrier to gas.

Material for Outside

Characteristic

PET

Normally is transparent.

Aluminized: Great barrier and microwave permeability, high temperature resistance.

AL

(Aluminum)

UV resistance, heat conduction, fragrance wrapping, oxygen and humidity resistance.

PA

(Nylon/Polyamide)

Heat resistance, wear resistance, puncture resistance, strong toughness and good softness. Good barrier to gas.

Material for Inside

Characteristic

PE

(Polyethylene)

Good heat sealing and moisture resistance, tear resistance, low temperature resistance, strong toughness. (Low transparency)

CPP

(Cast polypropylene)

High transparency, hardness and high temperature resistance.

Layers

Conventional Materials Matching

2 Layers

OPP + CPP/PE, PET + CPP/PE, PA + CPP/PE

3 Layers

OPP + PET + CPP/PE, PET + PET /AL/ PA + CPP/PE

4 Layers

PET + PA + AL + CPP

Above is general materials for reference firslty.

And there are many different materials and processing technology else also.

Welcome to inquire if any special requirement.