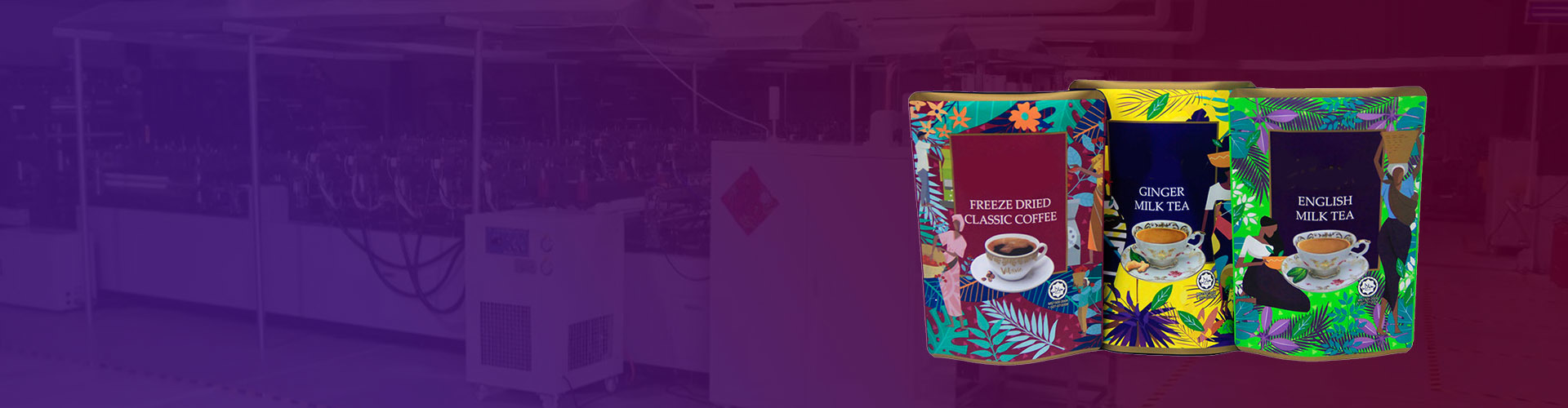

Custom Stand up Pouches Supplier

Custom your stand up pouches with different print, multi-colors, different material, shapes, and features. Low MOQ from 100 pcs, high quality printing, offer free sample delivery!

Stand up Pouches Supplier

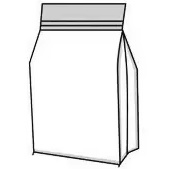

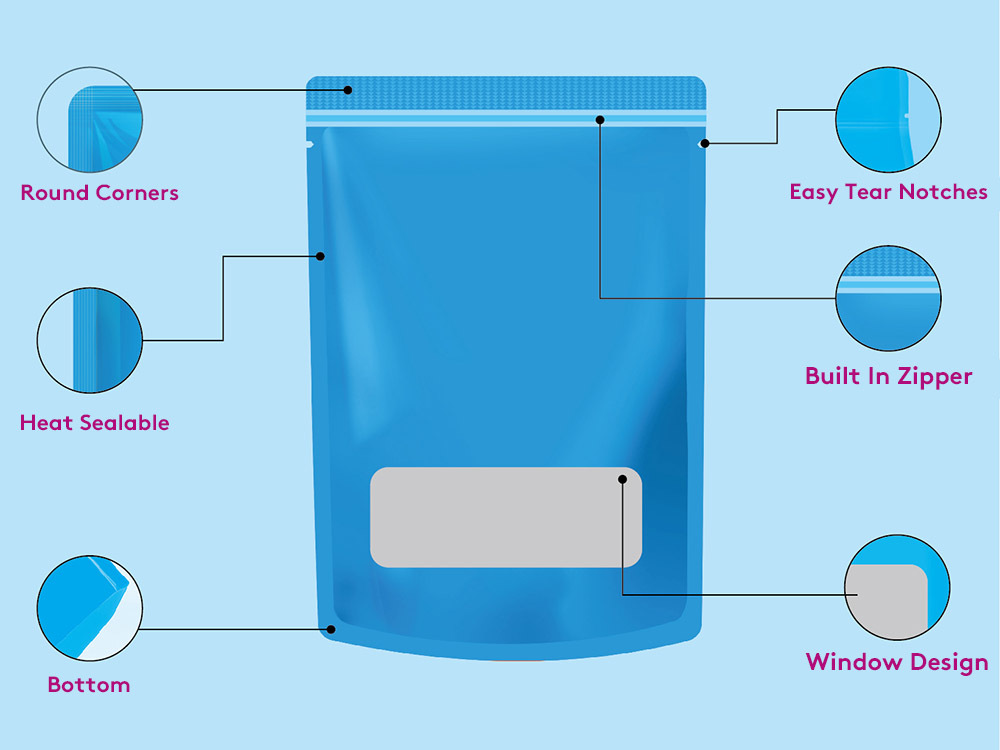

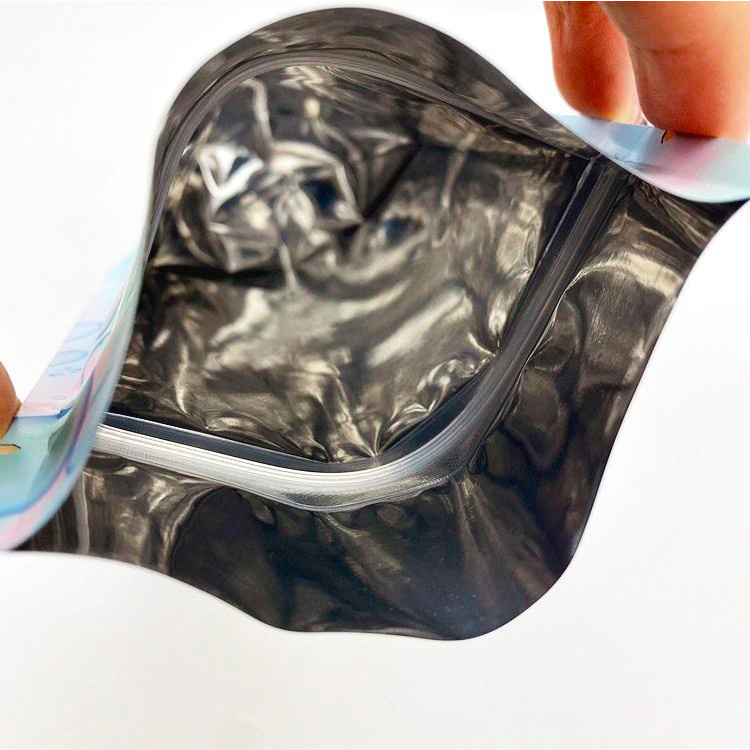

Stand-up pouches are a multi-layer(more than 2 layers film) laminated pouch, with a bottom gusset that can stand up on the shelf while filling with the product inside. Which is the most common use pouch in the nowadays flexible packaging market.

- All materials used are food-grade, FDA approved, and BPA free

- A shaped pouch also can be an option for standing on Shelves or table

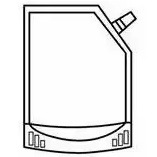

- Valve and spout, handle, window option available, with positive spout closure and degas ability

- Puncture resistant, heat sealable, moisture-proof, leak-proof, suitable for freeze, and reportable ability

WE CAN DO IT

★ Custom print with logo up to 10 colors, matte and spot glossy available

★ MOQ from 100 pcs for a start with digital print

★ Free exist sample delivery for reference

★ The shortest delivery time for printed pouches can be less than 7 days

Make your own Pouches

* Leave your contact information to get a free product quote

Stand Up Pouch Trending Compostable & Recyclable

Compostable Stand Up Pouch Made with Polylactic Acid(PLA) Material

100% Recyclable Stand Up Pouch Made with pure PE material

Post-Consumer Recycled(PCR) Stand Up Pouch made with PCR Material

100% Pure Kraft Paper Material Stand Up Pouch ( Plastic-free)

Compostable printed stand-up pouch’s MOQ can start with 100 Pcs.

Jingran are keep working and trending to develop better and better eco-friendly stand-up pouches for customers who need packaging products and services, welcome inquiry to us know more about our products.

If you want to customize your own stand up pouch, email us!

How to choose Valve | Spouts | Zipper | Material Options On different Stand Up Pouch?

The stand-up pouch is the most complicated and changeable flexible packaging option now. So if we need to choose the proper valve, spout, zipper, or material for a stand-up pouch, what should we consider before placing an order?

● Function at first prior: Make sure the valve, spout, zipper, or material used on the pouch can meet your limited function requirements;

● Style Appearance Preference: Make sure the spout shape, zipper reclosure, material characteristics creates something special compare to competitors;

● Cost Consideration: If you buy in China, using some big brand’s localized option will be always a good option, the cost will save at least 30%-50%;

● Simple feasibility: Sometimes if you are in a hurry in lead time, trying to replace something complicated with a simple version will save more time.

Send us an email or drop us a line, ask the expert now!

Stand Up Pouch FAQ

Q

What is a self-contained bag?

+

A

Self-standing bags are basically bags made of various plastic films, aluminum foil or other materials laminated.

The unique characteristics of these bags make them most suitable for creative advertising. Self-standing bag manufacturer

For example, a designer may decide to alternate them with logos, colors, and designs to improve the look.

It is for this reason that self-standing bags have revolutionized the world of product packaging.

Unlike some traditional packaging media, such as cartons and boxes, it uses fewer resources and is ideal for customization.

Q

Application of stand up pouch

+

A

Food storage like snacks, chips and biscuits, cookies, nuts, chocolate, candy packaging, etc.

Also widely used in sugar, spice, sauce, milk powder, oat, coffee, tea

Also, they can be used for detergent, toys, seeds, garments, etc.

With tight heat seal strength, it forms a good barrier to maintain freshness, flavor, fragrance, nutritional qualities of chemical potency of products.

Stand-up pouches can be widely used in various ways and involve many applications.

Q

Stand Up Pouches Types

+

A

Stand-up zipper pouch

Kraft stand-up pouches

Rice paper stand-up pouches

Stand-up pouches with window

Foil stand-up pouch

Shaped stand-up pouch

Stand-up pouch with spout

Stand-up pouch with valve

Q

Material for Shelf-life & barrier?

+

A

- High heat resistant structures: this type is made by laminating several layers of see-through film together to add the necessary barrier properties required to withstand microwave heat.

- Boilable structures: this type can be created by laminating either clear films or metalized layers together to form a single heavy-duty layer. Unlike microwaveable structures where foils cannot be used, this type can allow the use of metalized films.

- Aluminum structures: this type is most preferred due to its strong barrier properties when compared to other packagings. Aluminum foils can also be higher priced compared to their counterparts.

- Non-foil opaque structures: this material is popular for its durability, high strength as well as remarkable barrier properties. This structure does not allow consumers to have a look at the contents inside the package.

Common Accessories

Provide custom service

Suction Nozzle + Handle

Self-sealing Zipper

Easy Zipper

Slider Zipper

Material Choices

With a depth of experience in the flexible packaging industry, we're experts in flexible barrier packaging and all it entails, including consumer packaging. If you're on the search for or are curious about the best types of flexible packaging material, please read on to learn more about us, barrier bags, and our packaging barrier.

PE

Polyethylene is a thermoplastic polymerized from ethylene monomer, which is divided into high density polyethylene (HDPE), low density polyethylene (LDPE) and linear low density polyethylene (LLDPE) according to its density and molecular structure.

AL

Aluminum foil is a very thin sheet of metallic aluminum produced by a rolled process and is usually used in combination with other materials.

PA

The final product from these materials printable and is able to protect the content moisture, light, oxidation and odor. They form the best 3 side pouches for storing food products to prevent any staleness.

PET

PET is a high-strength, transparent thermoplastic with good barrier properties and processing properties.

PP

PP is a semi-crystalline thermoplastic with high strength and good chemical stability.

CPP

CPP is a polypropylene film produced by casting process, which has high transparency and good heat sealing performance.

RCPP

RCPP is a cast polypropylene film produced from recycled polypropylene material, which has environmental and cost advantages.

VMPET

VMPET is a material made by vacuum aluminization process on the surface of PET film, which has high barrier properties.

VLOPP

VLOPP is a material made by vacuum aluminization process on the surface of casting polypropylene film, which has good barrier properties and heat sealing properties.